Soft Rubber Hose Due to its construction, hydraulic hoses can be divided into following categories:

hoses with textile braid (one or two layers).

hose with one or two layers of steel wire braid (one, two and three layers).

hoses with spiral wire braid (four or six layers).

Hydraulic hoses are manufactured in imperial sizes and standardised. The most popular standards defining requirements for hoses are as follows: American SAE, German DIN, International ISO and European EN.

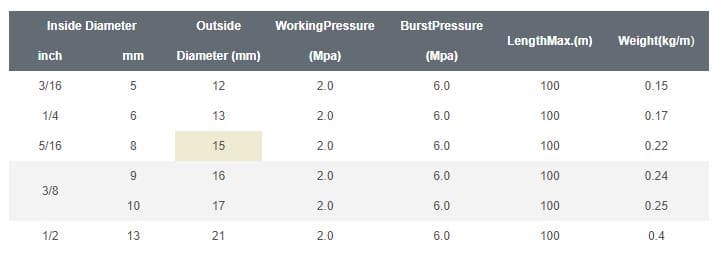

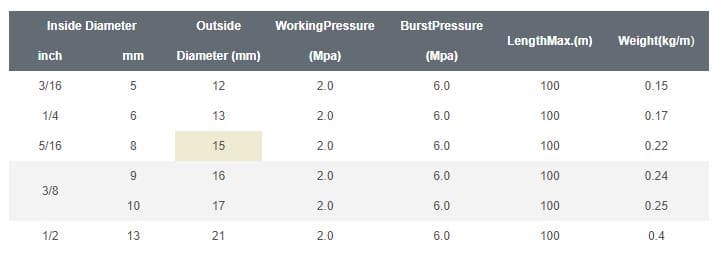

Application: Mainly used for conveying of oxygen and acetylene gases for welding and cutting equipment.

Tube: NR & SBR synthetic rubber, black color.

Reinforcement: High tensile synthetic yarn braided or spiraled.

Cover: NR & NBR synthetic rubber, red and blue etc.

Characteristics: Abrasion resistant, weather resistant and zone resistant. Its of pressure bearable, flexible, light in weight, anti-bending, less distortion and nice smooth surface.

Standard length: 30m, 50m, 100m

Temperature range: -20ºC to +60 ºC

Apart from standardised hoses (according to above mentioned norms) our offer includes hoses with increased flexibility, higher working temperature, increased abrasion resistance of external layer or better chemical resistance.

For a proper choice of

Hydraulic Hose to a particular application below mentioned aspects has to be taken into account:

working pressure and working conditions (static/dynamic),

medium and ambient temperature.

Hydraulic hoses designed for mining applications must fulfil additional requirements connected with explosives and fire conditions present in mines.

Hydraulic hoses assembled with the use of fittings crimped on crimping machines.

Rubber hydraulic hoses find their most common use among hydraulic systems, mainly for transporting oil-based liquids, but they can also be used for water systems. They are great at maintaining internal pressure due to their rubber and steel composition, so they`re commonly found in applications where you`re transferring power from generator to nozzle.

These flexible rubber hoses maintain their strength by using a reinforcement layer made from high tensile steel wire. An outer layer of synthetic rubber makes the hose resistant to oils, abrasion and weather exposure. You can build your own replacement hoses by combining bulk hydraulic hoses and attachments with our braided hose crimp fittings.

Rubber hydraulic hose is a common and important element in countless industrial and mobile machines. It serves as the plumbing that routes hydraulic fluid between tanks, pumps, valves, cylinders and other fluid-power components. Plus, hose is generally straightforward to route and install, and it absorbs vibration and dampens noise. Hose assemblies-hose with couplings attached to the ends-are relatively simple to make. And if specified properly and not overly abused, hose can work trouble-free for hundreds of thousands of pressure cycles.

Hydraulic hoses consist of an inner tube, one or more layers of reinforcement, and an outer cover. Each constituent should be selected with the intended application in mind. Typical operating and performance parameters include the size, temperature, fluid type, pressure-holding capacity and environment, to name a few.

The cover protects the reinforcement layer. One consideration when determining the cover material is resistance to attack from outside influences like chemicals, salt water, steam, UV radiation and ozone. Common cover materials include nitrile, neoprene and PVC, among others.

bend-radiusWhen a hose rubs against adjacent structures or other hoses, friction and abrasion can be concerns. That`s because if the cover wears away and exposes the reinforcement to mechanical and chemical attack, the hose will often quickly fail. A number of manufacturers offer tough, abrasion-resistant covers to help prevent harm.

The demand for ever-larger, off-road equipment was the impetus behind the development of spiral hydraulic hose. Today, it is well-suited for applications that see extremely high impulse pressures. As just one example, hydrostatic drives on large dozers and earth movers often rely on four and six-wire spiral hydraulic hoses.

Soft Rubber Hose Related Products:

high pressure hydraulic rubber hose

high temp rubber hose